|

CLICK HERE FOR DETAILS ABOUT THIS PICTURE:

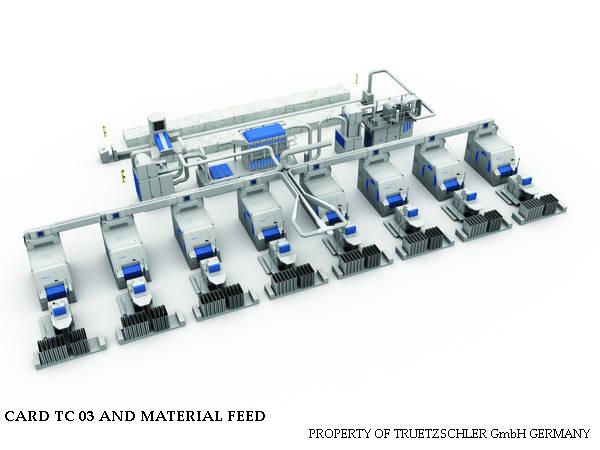

Carding-In yarn production, a process of separating individual fibres, causing many of them to lie parallel and removing

most of the remaining impurities.

Cotton, wool, waste silk, and man-made staple are subjected to carding. Carding produces

a thin sheet of uniform thickness that is then condensed to form a thick, continuous, untwisted strand called sliver. When

very fine yarns are desired, carding is followed by combing. Carded sliver is then spun.

Machine for carding textile fibres:

In

the 18th century, hand carding was laborious and constituted a bottleneck in the newly mechanized production of textiles.

Several inventors worked to develop machines to perform the task, notably John Kay, Oliver Evans, Lewis Paul, R. Arkwright,

and Johann Bodmer.

Carding- This plays a great and most important role in spinning especially regarding quality, why it calls as

"HEART OF QUALITY". The higher the speed may cause the danger

effects on quality.The carding machines production varies from 50 to 110 Kgs/hour.The feed is in the form of lap and end product

known as the Crad Sliver.

The main obectives of carding process are:

- To open the raw material lap into fibres(seprate),

- Removal of impurities (trash, seed coats etc.),

- Removal of dust,

- Elimination of Neps,

- Discharge the Short fibres,

- Fibre orientation

|